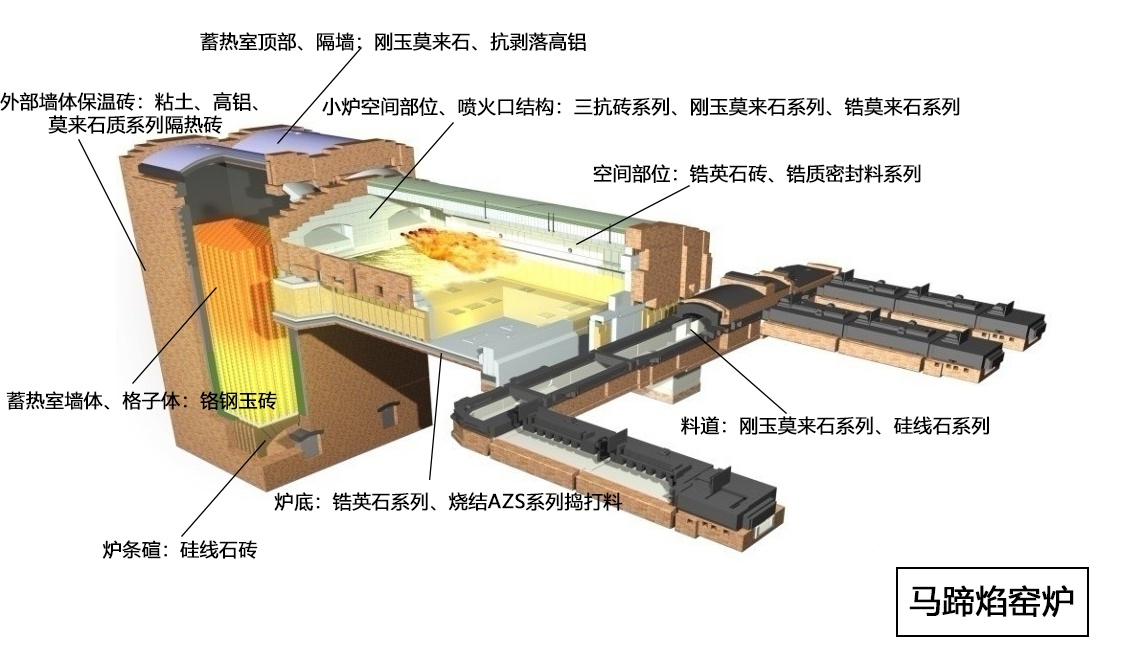

Overview of horse shoe flame melting furnace masonry construction project

The masonry construction project of the glass melting furnace shall be constructed according to the design. Materials for masonry construction project shall meet design requirements and current material standards. The glass melting furnace masonry construction project can only be carried out upon completion of the melting furnace foundation, kiln body skeleton structure and related equipment installation and after passing the inspection and signing the process handover certificate.

The process handover certificate shall include the following contents: measurement records of the furnace centerline and control elevation; acceptance records of concealed works; re-measurement records of the main dimensions of the installation location of the steel structure; inspection records of the quality of anchors and welding parts.

The following parts of the glass melting furnace shall adopt the dry masonry method: the bottom of the pool, the wall of the pool, the lower gap bricks, the superstructure built with cast bricks, the lattice bricks of the regenerative chamber and the parts where the design specifies dry masonry construction. Other parts shall adopt wet masonry method.

Except for the expansion joints or fillers specified in the design, the bricks of the dry-laid objects shall be close to each other without fillers. According to different requirements during construction, the refractory bricks in the dry-masonry part shall be selected, processed and pre-laid.